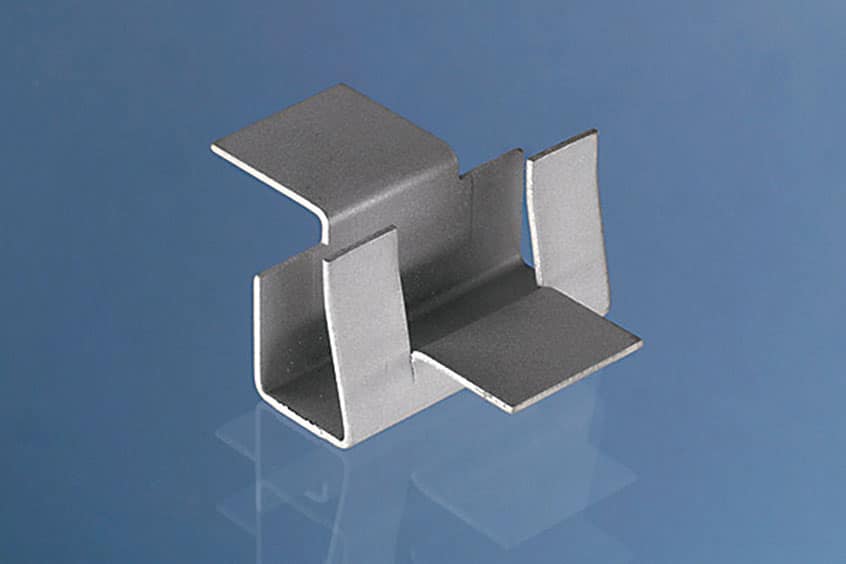

Proven a million times over, spring steel clips are used wherever components need to be positioned, fixed, combined or locked. The possible uses are therefore almost universal. In the tool industry, aviation, the automotive industry, in the electrical and electronics industry and in other areas, spring steel clips play their small but functional role in the overall productive process. Standard models do not always solve the specific problem. Here, individually tailored versions are the key to success.

Contents

Their name already expresses the most frequently used function: brackets. Wherever certain components have to be clamped, but also held or held in an exact position, spring steel clamps are used. Your advantage is the flexible handling. An important aspect is the possibility of quick assembly and disassembly of both the components to be clamped and the clamp itself.

Compared to other steels, spring steel has a strong elastic characteristic. For example, this material is found in car chassis as well as in clothespins. The material properties that are important here are elasticity and strength. A spring steel workpiece can be bent to a certain extent and then return to its original shape without being deformed.

Since elasticity is a special property that is important, this characteristic is achieved by manufacturing an alloy with the desired properties. One element for such alloys is the element silicon, along with numerous others. It is important for a steel component that is spring-loaded that the material hardness is optimally distributed over the cross-section. That is why the production process at Schaaf is aimed directly at ensuring this even distribution as early as the primary forming process.

Stainless steel is a designation for alloyed or unalloyed steels with a special degree of purity. In contrast to steel, stainless steel has better corrosion resistance, the difference being the sulfur and phosphorus content. Using the laser cutting process, spring clips made of stainless steel can be produced with almost no burrs and in an absolutely precise cut.

The flexible and versatile use in different industries makes the use of different materials necessary for production. Spring steel clips, especially their individual designs, are used in mechanical engineering, in connection technology, by lighting manufacturers, in electrical engineering and in the automotive industry. Stainless steel as well as steel, spring steel and non-ferrous metals are used. In addition, there are various processes for surface finishing such as galvanizing, painting, blackening, phosphating and tumbling.

The family of spring clips also includes detent springs, leaf springs and wire form springs. Depending on the application, they are made of flat or round material. When using flat material, spring clips are usually produced on automatic punching machines or CNC-controlled punching and forming machines. If round material is used, pneumatic and hydraulic bending machines are just as suitable for production as CNC-controlled wire bending machines.

Schaaf is the right address for anyone who wants to rely on uncompromising quality when it comes to spring steel clips. Whether small or large batch sizes, as a spring steel clip manufacturer, we choose the most suitable material, the right production technology and the required surface treatment and provide you with a product that will function reliably over the long term and exactly meets your expectations.

Rely on the experience of the specialist for sustainably successful technical springs!

Bitte geben Sie hier ihre Suchanfrage ein: