Since it is not always easy to find the optimal spring for the desired application, our design department takes on this complex challenge. In such cases, our engineers work closely with you to develop the right spring products. Functionality and efficiency are just as important as design and sustainability.

You send us your idea. We plan the right spring with you - regardless of whether it is a completely new development or further development as a product adaptation according to customer specifications.

Do you already have a drawing, sketch or CAD file? Send them to us and we will check them for coherence and feasibility.

If you would like your order to be processed particularly quickly and on schedule, you can also request our express service in your inquiry.

Based on your request, we will create a component test and you will quickly receive feedback on feasibility and delivery time.

We would be happy to provide you with an individual offer tailored exactly to your requirements.

After your order, we may contact you to clarify further necessary details. In most cases, however, all the general conditions can be clarified in an uncomplicated manner by e-mail.

Demanding applications require special springs according to their requirements. In such cases, our engineers are at your side with detailed advice. All decisive factors can be discussed directly with you in direct contact.

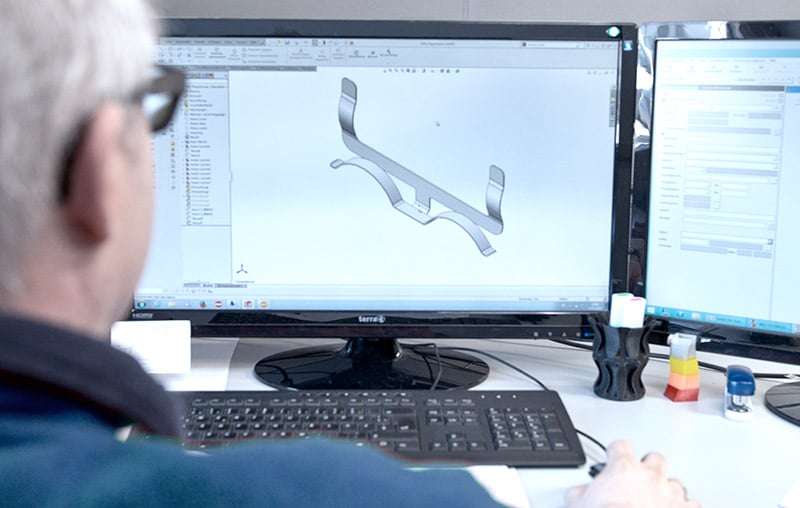

Our construction department will plan the technically efficient and most cost-effective solution for you, so that you receive exactly the spring that best suits your application and is needed later. You will receive a file as Step, DXF, SLDPRT or 3D PDF for verification.

In special cases, close cooperation may be required, in which we can dive into the design environment together with you via digital meetings and make direct arrangements and adjustments according to your specifications using 2D or 3D illustrations.

Then it goes directly into production with process-accompanying quality assurance.

We help you to refine your product, but above all to develop it faster and therefore more cost-effectively. We calculate our service according to the scope of the requested spring construction. You send us your request, your request – and we will make you an offer.

Bitte geben Sie hier ihre Suchanfrage ein: