- Home

- CAD Templates

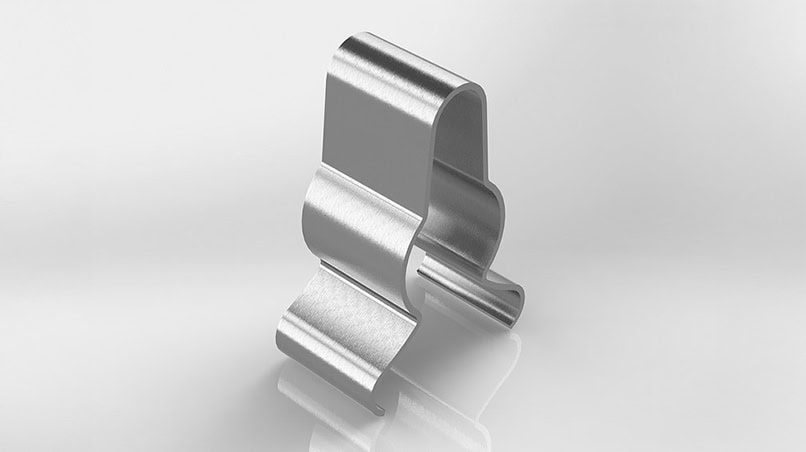

- CAD Template 01 - Flat Spring

- CAD Template 02 - Flat Spring

- CAD Template 03 - Form Spring

- CAD Template 04 - Form Spring

- CAD Template 05 - Form Spring

- CAD Template 06 - Form Spring

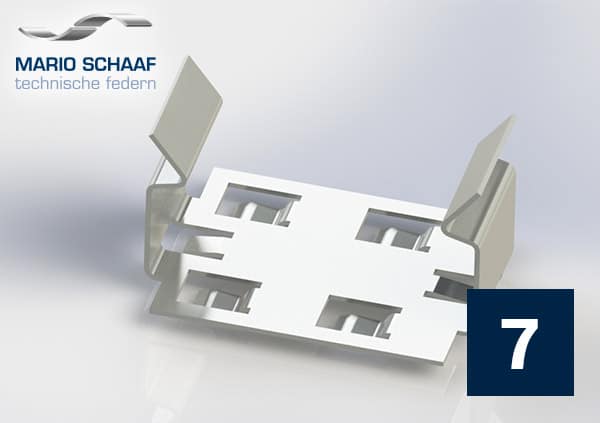

- CAD Template 07 - Spring Clip

- CAD Template 08 - Steel Spring

- CAD Template 09 - Form Spring

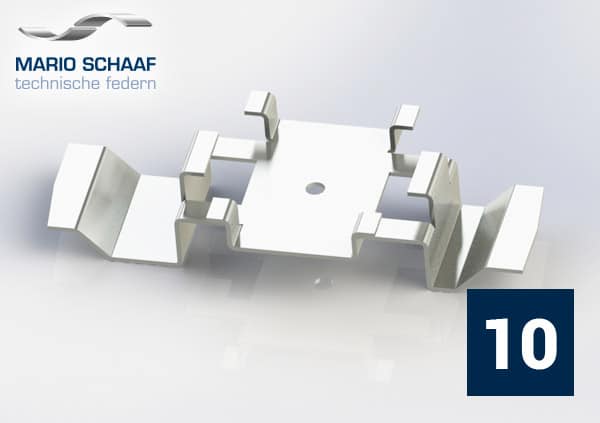

- CAD Template 10 - Flat Spring

- CAD Template 11 - Flat Spring

- CAD Template 12 - Spring Clip

- CAD Template 13 - Spring Clip

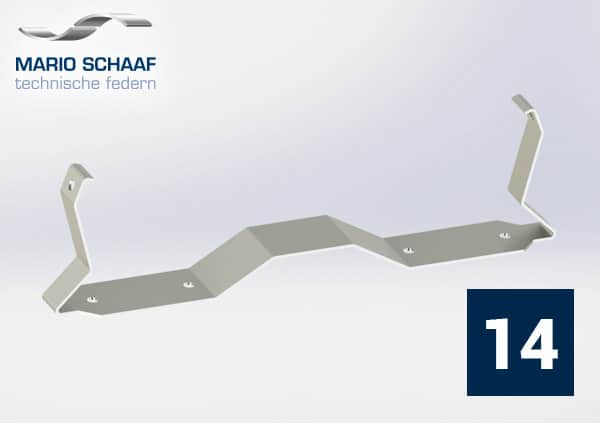

- CAD Template 14 - Flat Spring

- Products

- Service

- About us

- Jobs

- Topic-Blog

- Contact