Specialists for problem-solving strategies

Small springs, big impact. Inconspicuously hidden inside, technical springs are an integral part of everyday life. They make engines run, aeroplanes fly, electrical appliances work and cupboard doors close. And these little all-rounders can do much more: hold, clamp, press and make contact: A spring is the perfect connection solution and is cheaper and faster than a screw.

What may not seem very spectacular on the surface may turn out to be the solution to a highly complex problem on closer inspection. At Mario Schaaf Technische Federn, more than ten years of experience in problem-solving expertise is combined with a passion for unusual designs and the unconditional goal of finding the optimum solution.

Realising new tools is now easier and faster

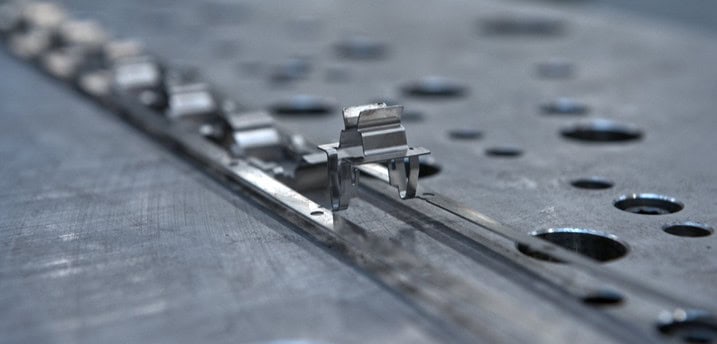

As a specialised metalworking company, Mario Schaaf manufactures technical springs to any specification. The range extends from flat, leaf and moulded springs to all types of bent wire parts and complex assemblies. Flat spring components, complex, three-dimensionally bent shapes or rotationally symmetrical bent parts are just one part of the portfolio; customised products are the speciality of the family-run company based in Möglingen.

Whether it's a hand sample or a prototype, large or small quantities, a highly complicated customised product or a complex assembly: Mario Schaaf Technische Federn reacts individually and flexibly to your requirements. Together we will develop a solution that is optimally customised to your needs. With express delivery, products can be produced and delivered within 24 hours.

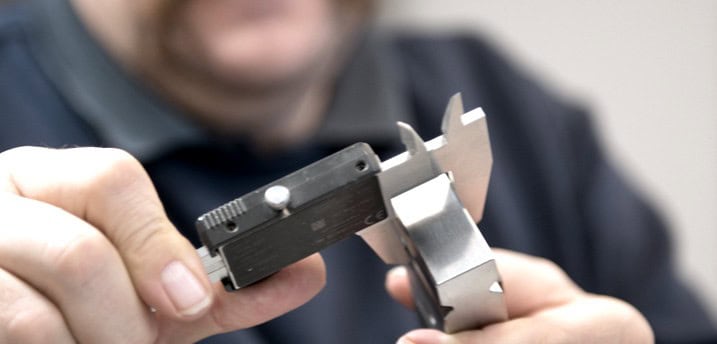

Top quality is a matter of course. This applies not only to the finished product. The company's quality assurance begins with the selection of reputable suppliers and the conscientious inspection of incoming goods and continues with the immediate processing of your order and adherence to exact delivery deadlines. Mario Schaaf Technische Federn combines the quality standards of large manufacturers with the flexibility of small companies. Individuality is our top priority - regardless of whether we are solving a specific technical problem or agreeing payment terms and delivery times that are customised to your needs.

References

Get in touch with us

You are in good hands with Ms. Dolata. With her friendly, personable manner, she can either help you directly or she can immediately direct you to the relevant person.

Marion Dolata

Tel.: 07141 49192-0

Mail: info@schaaf-federn.de

Your direct contact

High-tech & craftsmanship

Highly efficient, fully automated production

Precision down to the last detail

The diversity of the feather world

All metallic materials can be processed in the machine park, from stainless steel and non-ferrous metals to special steels with particular temperature, strength and magnetic properties. Material thicknesses from 0.1 to 3.0 mm are processed. The capacity of the machines ranges from 3 to 300 mm in width and from 1 to 1000 kilo Newton in tonnage.

Don't worry about difficult requirements! We advise you, develop and optimise the right technical spring for you and select the appropriate material and production technology. The result is your customised, sustainable spring solution.

Our success story

Mario Schaaf GmbH & Co. KG has stood for the highest quality and precision in all types of technical springs for more than two decades - whether leaf springs, flat springs, moulded springs, spring contacts or clamping claws.

Since the beginning in 1993, Mario Schaaf has been a guarantor for the successful development as a medium-sized problem solver for his customers.