Metal springs: a lot of strength and elasticity from which we usually benefit unnoticed. Whether in machines, appliances or alltag products - springs hold, clamp, lock and control numerous functions. But what types of metal springs are there, where are they used - and how are they created?

What types of metal spring are there?

There is a wide variety of metal springs. The most important designs include

- Flat springs and shaped springs

They are used wherever compact designs are required - for example in electrical switches, relays, fuses or in appliance construction. Their geometry can be designed variably, which makes them typical problem solvers in construction and apparatus engineering. - Leaf springs

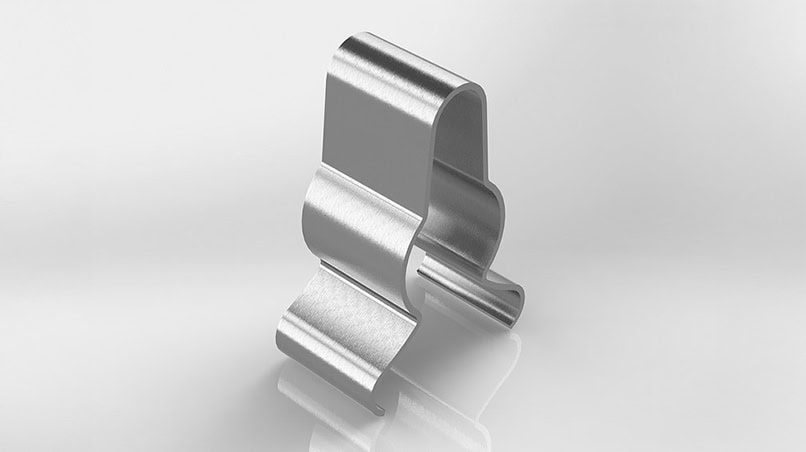

Used in mechanical assemblies, measuring and testing devices or locking mechanismswhere permanent elasticity and the absorption of higher forces are required. They are characterised by robustness and durability and are often part of complex devices. - Spring clips

Typical in the Montage and fastening technologyfor housings, covers or plug connections, for example. They enable quick, tool-free fixings - whether in medical technology, furniture construction or industrial assemblies. Depending on the requirements, spring clips can also be Extremely heat-resistant (→ [further article on the heat resistance of springs]) and at the same time Reduce vibrationswhich also makes them ideal for use in demanding environments. - Contact springs

Indispensable in Electronics and electrical engineering: They establish safe electrical connections, for example in Sockets, printed circuit boards or switchgear. They also ensure precise contacting in precision mechanical assemblies. - Bent wire parts

The flexible solution when standard moulds are not sufficient. They are bent according to individual specifications and are used in Medical technology, precision engineering and device constructionwhere complex geometries are required. - Extension springs, compression springs and torsion springs

The classic spring types for Power transmission and energy storage. Used among other things in Mechanical engineering, drive and connection technology, or in electronic and household applianceswhere resilience and functional reliability take centre stage.

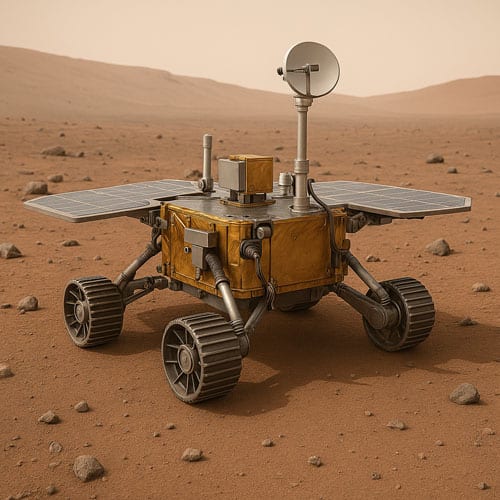

The spectrum therefore ranges from the smallest alltags such as the springs in a socket to safety-relevant applications in cars and high-tech solutions in space travel, where springs in Mars landers ensure absolute precision and reliability.

Where are metal springs used?

When you think of springs, you usually have the image of a simple spiral in your head. In reality, however, there is much more to metal springs: they are silent players that make our technology work in the first place. We encounter them almost everywhere in the Alltag - often without even realising it. Even a standard power socket contains several small contact springs that ensure that electricity flows reliably. In kitchen appliances such as toasters or coffee machines, they inconspicuously perform important tasks such as holding, switching or steaming.

With increasing size and complexity, the tasks also grow. In cars, for example, springs not only ensure comfort, but also our safety: from seatbelt buckles and switch contacts to retaining springs in the vehicle interior. And at the other end of the spectrum are applications in high technology - where metal springs have to function under extreme conditions. In aerospace projects, such as in Mars landers, they are designed to work absolutely reliably even under vibration, vacuum and temperature fluctuations.

The spectrum ranges from tiny spacetags to high-tech components in aerospace. This makes it clear that metal springs are not banal components, but precisely developed design elements that are indispensable in an astonishing variety of industries and areas of application.

It may also be necessary to carry out individual production steps manually when manufacturing metal springs. This is particularly the case when special designs, complicated components or complex assemblies are required. In these cases, the stamping and bending work is carried out manually.

How are metal springs manufactured?

The manufacture of metal springs is a combination of design, precise engineering, modern production technology and material-appropriate processing. This is because a spring is not a mass-produced product, but in many cases a customised component that must be precisely matched to the load, environment and function.

Step 1: Construction - the beginning of each spring

Before the first machine is started up, the design phase begins. Engineers develop the geometry and function of the spring precisely according to the customer's specific requirements. It's not just about shape and size, but also about force ratios, installation environment and service life. With modern CAD systems, even complex spring shapes can be simulated and optimised before production starts.

However, the work of the design engineers does not only start with new developments. Even if customers already have existing technical data or 3D models, Schaaf Federn carefully scrutinises every project:

- Feasibility analyses ensure that the design is technically feasible.

- Collision checks prevent problems in production.

- On request, the data supplied can also be checked for functional optimisation or production efficiency.

The result is an end-to-end process in which design and production work hand in hand - with the aim of delivering the best possible solution for every application.

Step 2: Punching and forming technology

Many springs start with a metal strip or sheet, which is processed in ultra-modern systems. In stamping technology, components are removed from the material using precise cutting tools. The bending technology then takes over, bringing the stamped part into the desired geometry. Punching and bending technology is particularly efficient, merging punching and bending processes on CNC-controlled high-performance machines in an automated process.

Step 3: Post-treatment - surface as the key to performance

A spring is more than just its shape. The surface treatment often determines its durability and functional reliability. It protects against corrosion and wear, improves fatigue strength or provides special properties such as insulation or optical refinement. Various processes are used for this:

- Mechanical treatment: Preparation of the workpieces and general improvement of the surface. Typical processes include vibratory grinding (barrel finishing) for deburring, edge rounding, polishing and smoothing.

- Thermal treatment: Heat treatments that improve strength or relaxation resistance.

- Chemical treatment:

- Phosphating for corrosion protection, insulation or as a base for paintwork

- Burnishing for a coloured surface design

- Galvanising for long-lasting corrosion protection

- Lacquering for visual enhancement, additional contact reliability and protection

This means that each spring can be precisely matched to its subsequent application - from the Alltags device to high-temperature applications.

Step 4: Craftsmanship meets high-tech

Not every spring can be manufactured fully automatically. Even today, complex assemblies or highly customised geometries still require manual work steps - precise manual work that complements the industrial process. The interaction between digitally controlled machines and experienced skilled workers ensures that even customised products work reliably.

Step 5: Quality as a constant companion

From the initial design idea to the finished spring: quality assurance is not a step at the end, but a process throughout the entire production process. Tests for dimensional accuracy, resilience and fatigue strength are carried out continuously throughout production. This is the only way to create components that work reliably in highly sensitive applications - from medical technology to aerospace.

What materials are used for metal springs?

The choice of the right material is decisive for the functionality, durability and application possibilities of a metal spring. Different materials are used depending on the load, temperature, environment and desired service life.

Range of materials for Schaaf springs

- Material types: steel, spring steel, stainless steel and non-ferrous metals

(e.g. copper alloys, nickel-based alloys) - Material thicknesses: 0.10 mm - 3.0 mm

- Material widths: 1.00 mm - 270 mm

This allows a wide range of spring types and sizes to be covered - from the smallest precision parts to heavy-duty industrial components.

Important material types and their areas of application

Mechanical assemblies in mechanical engineering

Applications where a high spring force is paramount

Medical technology, where corrosion resistance is crucial

Contact springs in electrical and electronic assemblies

Precision mechanics, where processability and corrosion protection are required

Protective and retaining springs in consumer goods

Marine technology and wet rooms

Springs in medical technology and sterile applications

Industrial springs in devices with high loads

Applications with alternating continuous load

Explosion-protected areas (e.g. oil and gas industry)

Precision springs in measurement and control technology

Aerospace, where extreme loads prevail

Springs in turbines and high-pressure systems

Engine and turbine construction

Applications that require high strength and temperature resistance at the same time

Spring steel in comparison

Compared to other steels, spring steel is characterised by its high strength, hardness and toughness. Depending on the grade, it also offers advantages in terms of weight and corrosion resistance. It is particularly valued in precision mechanics and precision engineering, where small dimensions and high performance are required.

How long does a metal spring last?

The short answer: as long as tension, temperature and application profile allow. The long answer begins with the definition: A spring is durable if it works over its intended spring travel without loss of force, does not deform plastically and does not break - in other words, the stresses that occur remain permanently below what the material can bear.

Elastic vs. plastic - the limit of function

Metals initially deform elastically and return to their original shape when the load is released. If the load becomes too great, plastic deformation begins - the component remains "set". Purely elastic operation is therefore mandatory for technical springs; it can be categorised using Hooke's law and the material characteristics.

Two enemies of service life: creep/relaxation and fatigue

- Crawling & relaxation (Relaxation):

Under constant load, a spring can lose length over time (creep) or reduce load with constant compression (relaxation). The main drivers are stress level, temperature and time. At higher temperatures, these processes accelerate - the spring "relaxes". - Fatigue (fatigue strength):

When subjected to pulsating loads below the yield point, microscopic cracks start, which grow with the load amplitude and, in extreme cases, lead to fracture. Risk drivers are the nominal stress value, pulsation amplitude and the material limit; corrosion and temperature additionally weaken the fatigue strength.

In practice, the service life is statistically verified using fatigue tests and fatigue strength diagrams - this allows fracture probabilities and safe working ranges to be defined.

What specifically determines the service life

- Load spectrum:

Maximum force, amplitude, mean voltage, number of load cycles. - Temperature profile:

Continuous operation at elevated temperatures favours relaxation/creep and reduces vibration resistance. - Surroundings:

Corrosive media and moisture promote crack initiation and reduce fatigue strength. - Choice of material & surface:

Suitable alloy + surface treatment (e.g. corrosion protection) stabilise the characteristic values over the service life. (For more details, see point 5/"Post-treatment"). - Design & manufacturing:

Geometry, notch effect, tolerances and clean manufacturing processes avoid stress peaks - the most common source of early fatigue. (Implicitly from the testing/QA arguments described there).

What does this mean for your application?

Service life is not a fixed catalogue value, but the result of correct design, suitable material, clean production and consistent quality assurance - which is precisely why tests (dimensional accuracy, fatigue, environmental influences) accompany the entire process. For demanding tasks, it pays to work with specialists who bring together materials science, physics and manufacturing practice.

Read more: Durability of technical springs - Optimise service life (internal technical article with basics, influencing variables and diagrams).

Metal springs from the specialist

Anyone who uses a technical spring expects reliability - for many years to come. This is precisely where the strength of an experienced specialist comes into play. At Mario Schaaf GmbH & Co. KG, design, materials expertise, vertical integration and quality testing are interlinked and form a consistent performance promise.

- Construction servicece:

Experienced engineers are on hand right from the early stages. Whether it's a completely new spring design or a review of existing CAD models - every solution is checked for feasibility, collisions in production and optimisation potential. If required, an adaptation can be made to improve functionality, service life and manufacturability in equal measure. - Experience with complex requirements:

A wide range of industries - from medical technology and mechanical engineering to aerospace - rely on Schaaf. This wide range of projects creates expertise that goes far beyond standard solutions. - Material science and material knowledge:

Whether classic spring steel, high-alloy stainless steels or nickel-based alloys for extreme conditions - the material selection is always tailored to requirements. Knowledge of the special features of each material is the key to durable and resilient components. - Finishing and surface treatment:

Mechanical, thermal and chemical processes are used to prepare the surface specifically for use - from corrosion protection and electrical insulation to high-gloss or functionally coated surfaces. The result is not just a spring, but a component with precisely defined properties. - Manufacturing options:

Modern CNC and stamping and bending technology enables high-precision series production, supplemented by manual production for complex customised solutions. The high level of vertical integration ensures flexibility and efficiency. - Quality assurance:

Every spring undergoes rigorous testing processes. Load tests, measurements and simulations ensure that every part works reliably in real-life applications - whether in a socket, a surgical instrument or a space system. - The result:

customised solutions with maximum precision that combine functionality, economy and durability.