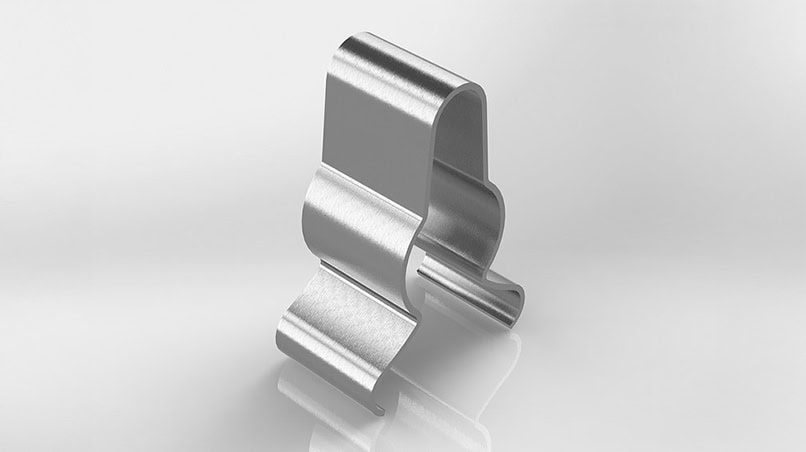

EMC contact springs are spring elements for preventing electromagnetic interference. Designed for special functionality, they enable the smooth operation of machines and systems by preventing electromagnetic or electrostatic interference.

The manufacture of EMC contact springs also requires customised solutions that go beyond the standard, and Schaaf is the first port of call for their realisation.

What does EMC mean?

EMC: Electromagnetic compatibility

The term EMC therefore stands for electromagnetic compatibility and plays a role in machines and systems in which electrical drives operate. The aim of EMC measures is to ensure that various electronic devices can be operated in the immediate vicinity without causing interference.

EMC is the ability of a technical device not to interfere with other devices through electrical or electromagnetic effects.

EMC contact springs prevent electromagnetic fields and absorb mechanical vibrations. The spring elements are designed to prevent faults, such as interactions and feedback inside and outside the device, by effectively dissipating interference currents.

EMC shielding and EMC springs

EMC spring contacts ensure that interference fields cannot cause any damage!

A large number of machines and production systems are driven electrically nowadays. Depending on the application, such a drive can be controlled steplessly using frequency inverter technology.

In addition to numerous advantages, frequency inverter technology also has the disadvantage of emitting strong electromagnetic interference fields via the motor connection cable. Without EMC shielding, sensor cables could interpret this as a signal and switch on the wrong functions. High overvoltages in the cable are also possible. In such cases, EMC springs ensure that interference fields cannot cause any damage.

Where are EMC contact springs used?

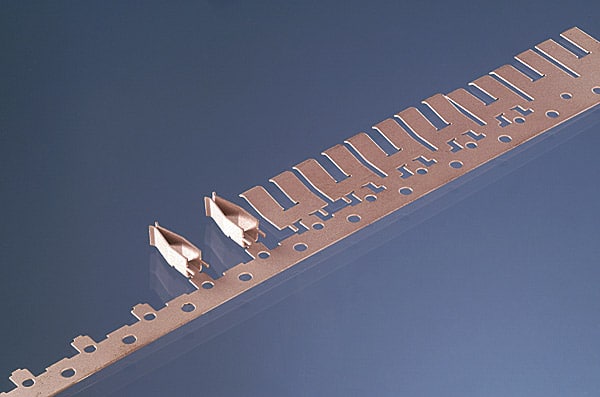

Because of the particularly good material properties, EMC springs are mainly made of galvanised spring steel or copper alloys such as copper-beryllium. In addition to the above-mentioned areas of application in electrically driven machinery, the following industrial sectors in particular use EMC contact springs in static and dynamic applications.

Fields of application for EMC contact springs:

- Communications and high-frequency technology

- Electrical engineering

- Building technology

- Measurement and control technology

- Automotive engineering

- Aerospace

- Nuclear physics

- Data processing and telecommunications

Quality of EMC springs

How is the quality of EMC contact springs tested?

A consistent quality concept is important for contact springs for EMC applications. The spring quality is measured from product development through production-related tests to final testing.

EMC tests

To ensure that EMC contact springs function optimally, EMC tests are carried out to analyse their immunity to external interference. In addition to EMC measurements as part of this test, shielding attenuation measurements are also carried out. In both cases, a basic distinction is made between conducted interference and interference caused by electric and magnetic fields or radio waves.

EMC regulations

Different EMC regulations depending on the area of application: EMC tests are organised according to different requirements for electrical or electronic systems. It is therefore obvious that higher requirements are placed on the reliability of aeroplanes than on consumer electronics.

Accordingly, the specific test and measurement methods for information technology, industrial, automotive, aerospace, military and medical technology are different.

Expertise is in demand

Experience and expertise are decisive criteria for those who do not want to compromise when it comes to electromagnetic compatibility and contact springs for EMC applications.

Schaaf is a partner that numerous companies trust when High-precision contact springs of special quality are required. As specialists for tricky tasks as well as standard solutions, the Schaaf experts look forward to finding the optimum solution to your problem.