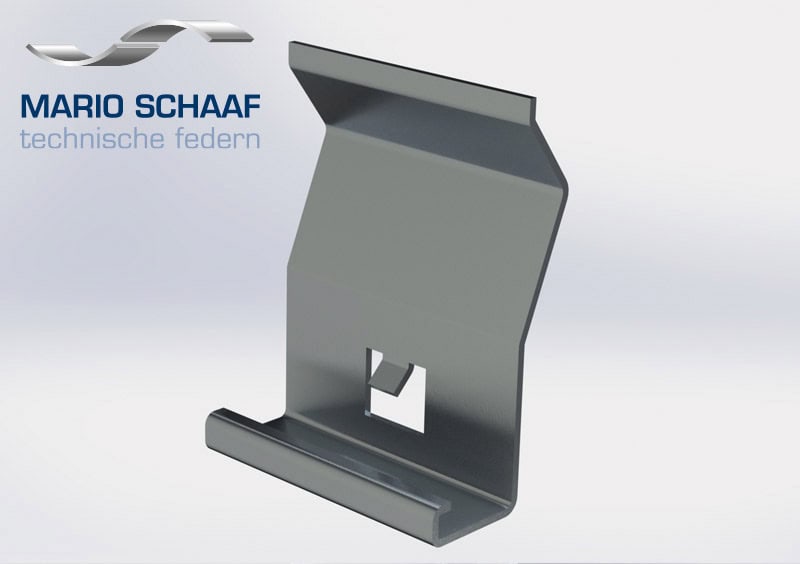

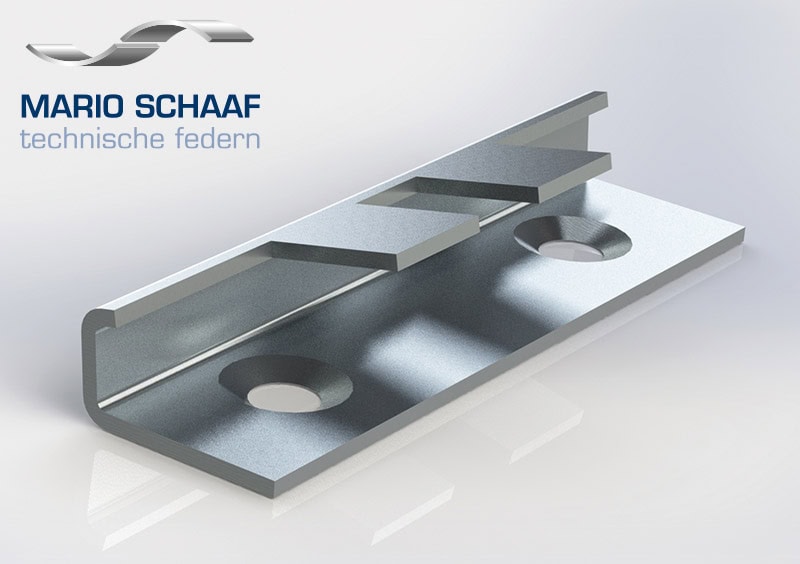

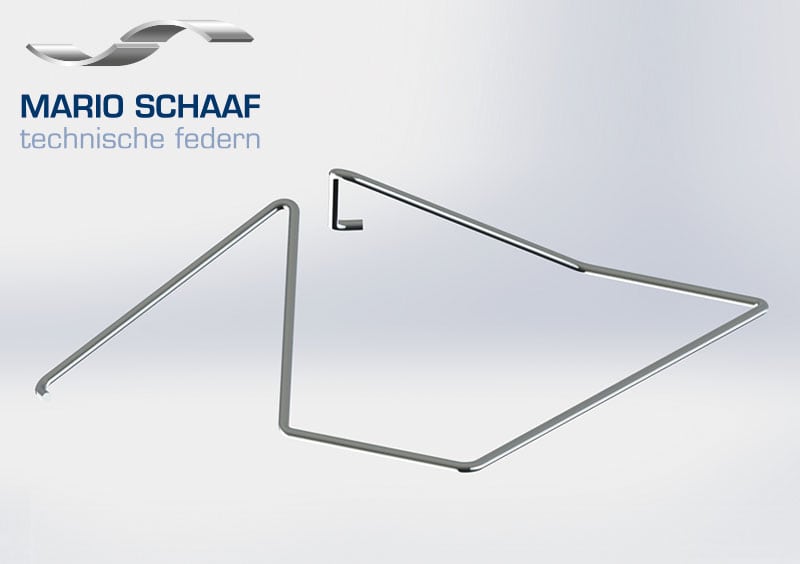

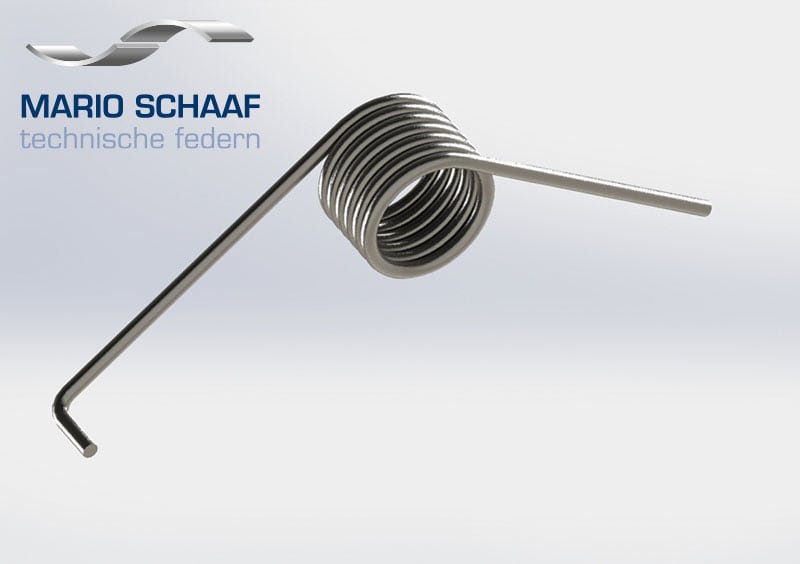

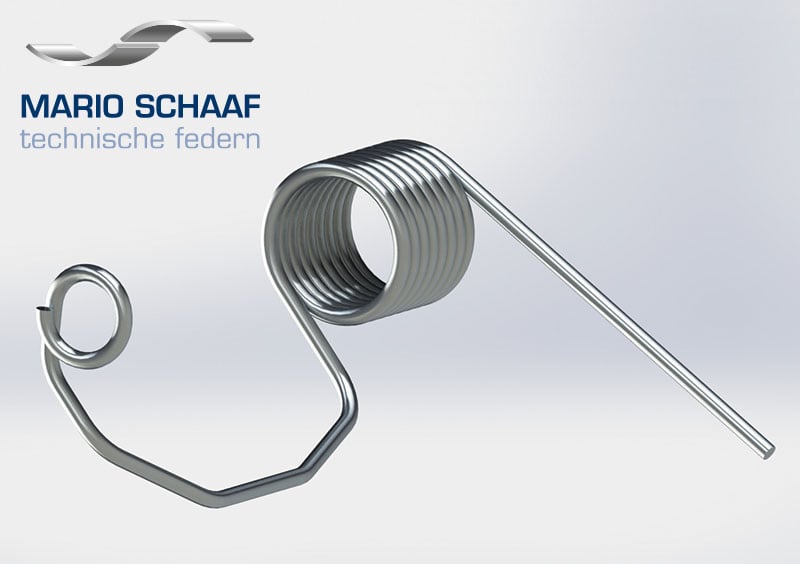

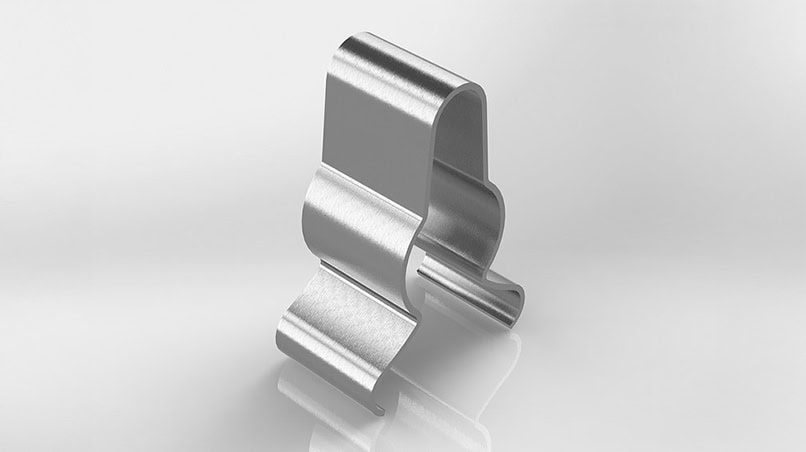

Mario Schaaf Technische Federn GmbH & Co. KG not only manufactures technical springs and bent wire parts of any specification. Custom-made products and complex assemblies are the specialty of the company's designers. If you don't yet have a clear idea of what your component should look like, you can rely on our experts.

The more demanding the job, the better. As a specialist in problem solving, Mario Schaaf GmbH & CO. KG tailor-made spring products, individual components of all kinds and develops unusual solutions.

Many of our customers do not approach us with a specific product request, but rather with a task. We would be happy to help you find the right solution for your requirements .

Just get in touch with us if you need springs made to measure and in special designs.

We look forward to your inquiry!

Good is not enough. Mario Schaaf Technical Springs strives for the perfect solution. Every request is a new challenge that we are happy to face. We develop individual solutions for you, from the idea to the right prototype to series production.

If you already have a rough idea of what your component should look like or already have a sketch, a CAD drawing or a If you have a prototype, you have come to the right place with our metalworking specialist company. Our designers continue to develop components,improve them and coordinate the material, production technology and surface treatment in such a way that an optimal solution is created.

Whether prototypes, small quantities or large series - you can rely on the proven quality of our modern production facility. From the goods receipt of our raw materials to the goods issue of our spring products.

All springs are made to measure in fully automated production. Continuous test controls guarantee the highest possible part precision and repeatability..