It starts with an adhesive. Perfectly harmonised in the laboratory and smoothly applied in production, it is designed to permanently bond two metal parts. But under real conditions - in a vehicle exhaust duct, where heat, vibrations and time have their effect - it reaches its limits. Under full load, the temperature exceeds the specification, the adhesive softens and the bond fails.

This is exactly what happened in a series vehicle - with the result that entire parts of the exhaust air system became deformed or detached. The cause: a design that relied on adhesive bonding, even though the thermal loads were significantly higher than expected.

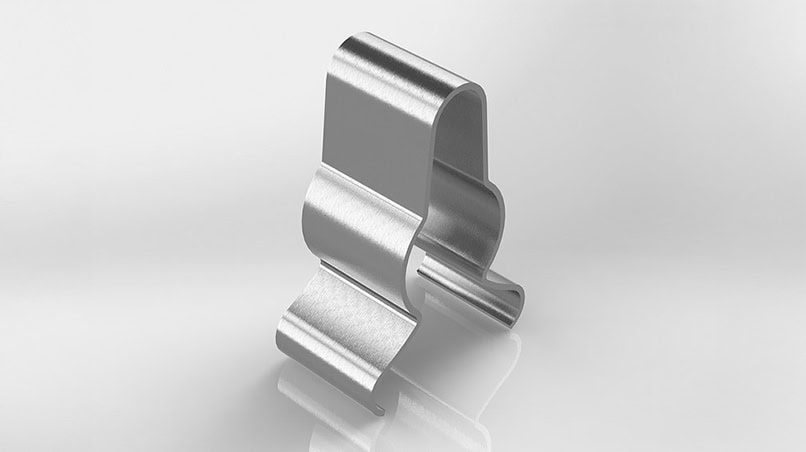

The solution did not come from the catalogue, but from the toolbox of physics: Technical springs - precisely manufactured clamps made of spring steelthat mechanically fix the exhaust air pipe. Without adhesive. Without weak points. And reliable up to the thermal load limit of the material.

From the splice to the clamp

The design change began inconspicuously: instead of gluing the exhaust air duct at its ends, a mechanical connection with the help of spring clips was used. A simple but ingenious solution - because it no longer shifted the load to a thermally sensitive adhesive layer, but to an elastically pre-stressed metal part with clearly defined forces.

Technical springs such as these clamps act with controlled tension - Their holding force is created by the targeted forming and the restoring force of the spring steel. And it is precisely this property that is retained as long as the material retains its mechanical strength.

The material used: 1.4310a stainless spring steel with high tensile strength, tried and tested in automotive engineering. Its limit is approx. 250 °C. Above this threshold, the material begins to soften - the holding force decreases and the clamp loses its function.

However, in the case of the exhaust air duct, this was sufficient: the temperature range levelled off below the critical mark after the design change. The clamping solution worked - and still does today. The adhesive was history.

Materials at the limit - when steel is no longer enough

For many applications in vehicle construction, mechanical engineering or process technology, 1.4310 is the standard: economical, rustproof, reliable - as long as the temperatures remain within limits. But what happens when they don't?

With Temperatures above 250 °C the spring steel begins to change its original structure. The yield strength decreases, creep deformation occurs and the spring effect diminishes. If you put your trust in the wrong material, you will pay the price with gradual failure - and ultimately with downtime or damage.

For more demanding scenarios 1.4568 (17-7 PH) is used. The steel is precipitation hardening and allows continuous loads up to approx. 300 °Cand even more at peak times - ideal for dynamically stressed springs that have to remain under tension for a long time. But even here, the end comes at some point.

Overview of materials and the respective areas of application in °C

The answer for extreme cases: Inconel.

These Nickel-chromium alloysoriginally developed in the 1940s by the International Nickel Company, are made for applications where other materials have long since become soft:

- In exhaust tracts of turbochargers,

- in gas turbines,

- in furnaces in the semiconductor industry or

- in the aerospace industry.

The best-known representative, Inconel X-750, defies Permanent temperatures up to 700 °C - even significantly more for a short time. It not only retains its shape, but also its mechanical preload. This is crucial for technical springs: No relaxation. No spring fatigue. No failures.

The price for this: complex processing, significantly higher material costs - and manufacturing expertise. This is precisely where the expertise of Mario Schaaf Technische Federn comes into play.

Hot coated - precision in the embers

Temperature also plays a destructive role beyond the automotive industry. In the Tool coatingwhere drills, milling cutters and cutting inserts are coated with hard, thin layers such as TiN or AlTiCrN, this is done under extreme conditions: Temperatures from 800 to over 1000 °Cvacuumised oven chambers, long holding times, precisely defined positioning.

A customer of Schaaf Federn was faced with precisely this challenge: How can sensitively moulded tools be reliably held in the oven - without their position changing due to thermal expansion? Screws? Too time-consuming. Hanging? Too imprecise. Gluing? Unthinkable.

The solution: Technical retaining springs made of high-temperature-resistant special alloys. They grip the mould with a positive fit, fix it to frames or supports and retain their elasticity - even at temperatures at which normal metals have long since creeped or failed.

Depending on the furnace type, alloys such as Inconel 718which have been specially developed for such extreme environments. The advantage:

- No contact deformation of the workpieces,

- High reusability of the spring systems,

- Minimum tolerance deviation despite the constant heat.

These brackets were developed in close co-operation between the customer and the designers at Mario Schaaf Technische Federn. Material selection, geometry, preload - everything has been adapted to the thermal behaviour. The result: a system that was moulded under fire - and withstands the fire.

Conclusion - Small feathers. Big effect.

What looks like a small piece of bent metal is actually a high-performance component: Today, technical springs perform tasks that used to be glued, screwed or improvised. They fix exhaust air ducts in vehicle construction, keep cutting tools in shape in annealing furnaces - and they do this where conventional materials have long since failed.

It is not only the geometry that is decisive, but also the material: 1.4310 for solid Alltags, 1.4568 for dynamic loads and temperature peaks - and Inconel when physics reaches its limits.

Mario Schaaf Technische Federn knows these limits. And knows how to push them. Through Precision-manufactured clamps, retaining springs and customised solutionsdeveloped in dialogue with customers, tested under real conditions - and adapted down to the last technical detail.

Success is not reflected in press releases, but in exhaust air systems that no longer decay. In oven processes that remain constant. And in components that deliver what they promise - even when things get hot.

Surface treatment and finishing Schaaf Federn offers the following processes, among others, to ensure that springs function optimally and are durable in the appliance environment:

- Trowalising for smoothing

- Phosphating, burnishing or galvanising for surface protection

- Painting if an optical or functional coating is required

Are you looking for a staple as an alternative to gluing?

We are happy to support you in developing the right technical spring - precisely tailored to your requirements.