Technical springs can be found in almost every machine design. Whether as connecting and storage elements or as a component element for measuring, resting and securing elements. With their different functions, these all-rounders are extremely versatile.

Machine elements Springs

Machines consist of many different mechanical components. These components or machine elements are either individual parts or more complex assemblies, which in turn can be made up of individual components. They are found not only in machines, but also in systems, apparatus and other devices.

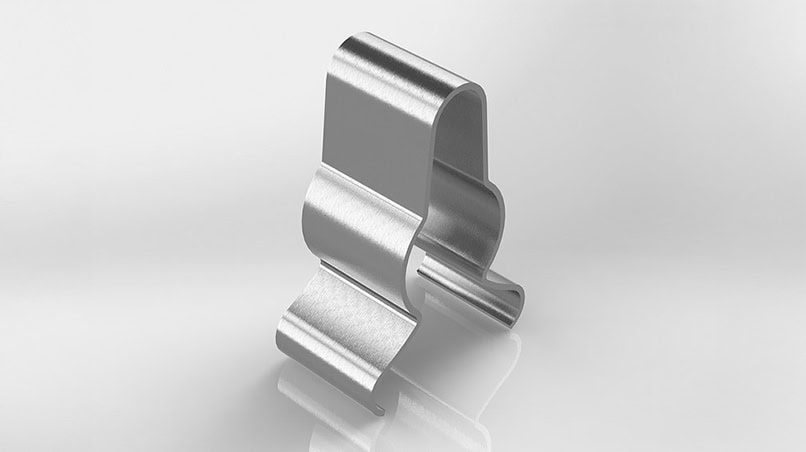

As machine elements, screws are usually used to connect and fasten components. On the other hand Technical springs - real all-rounders. Flat springs, moulded springs, flat moulded springs, Contact springs, Compression springs, tension springs and torsion springsare used as storage, vibration, resting, measuring and bearing elements. They can therefore fulfil very specific functions depending on the application and force state.

Spring forces in mechanical engineering

- Restoring force / counterforce

- Compressive force / adhesive force

- Equalising force

- Weight force / load distribution

- Driving force

- Vibration force / damping force

The smooth functioning of machines

Springs are often underestimated due to their inconspicuousness. However, they are indispensable, especially as the smallest machine elements, depending on their intended use. They solve engineering problems and are therefore fundamental for designs in plant and mechanical engineering. Snap rings are used, for example, as locking elements to prevent axial displacement of positive-locking components. Cotter pins are used in mechanical engineering to secure nuts, crowns, axles and bolts. And locking clips are used for additional fastening of screw connections and secure the connecting elements against unintentional loosening.

Mechanical engineering Spring: a small element with a big impact

What installation space is available in a machine?

If targeted holding, latching, fixing or damping of shocks and vibrations is required for other machine elements, customised Spring elements with limited space ideal results are achieved. In the article Springs for robotics describes how it would hardly be possible to generate important movement functionalities in robotic systems without the use of technical springs.

In addition, the Durability of technical springs for perfect function and constant properties in continuous use. Under extreme conditions, reversible changes in shape under load and high elasticity limits must be possible.

Mechanical engineer develops machine with spring elements

Springs for modern mechanical engineering technologies

We, Mario Schaaf GmbH & CO. KG, know that new technologies not only require customised concepts, but also economical solutions. That's why we rely on state-of-the-art production techniques and high-quality materials (Spring steel and spring steel strip).

Optimise your mechanical engineering projects and benefit from our many years of experience with individually designed and manufactured technical springs.