In medical technology, maximum precision, absolute reliability and long-lasting function are essential - especially for mechanical components in medical devices. Technical springs play a central role here: they are used in automatic analysers, dosing systems, jolting devices or surgical equipment as resetting elements, holding or clamping mechanisms and ensure smooth movement sequences in complex device structures.

Technical requirements for springs in medical devices

Medical technology devices must meet the highest quality standards. The requirements for all installed components are correspondingly high - including the springs. These must:

Be corrosion-resistant

for permanent use in sterile, moist or chemical environments

Be durable and resilient

Even with high switching frequencies or continuous load

Be manufactured with precision

with tight tolerances for miniaturised installation spaces

Be documentable and traceable

for regulatory requirements in the medical environment

Typical applications of springs in medical technology

Schaaf develops and produces springs that are specially designed for use in medical devices and technical environments. Typical areas of application are

- Clamping and holding mechanisms in operating theatre or analysis devices

- Contact springs in module connections or device interfaces

- Damping elements for vibration reduction in vibrating equipment

- Reset functions in dosing pumps or mechanical controls

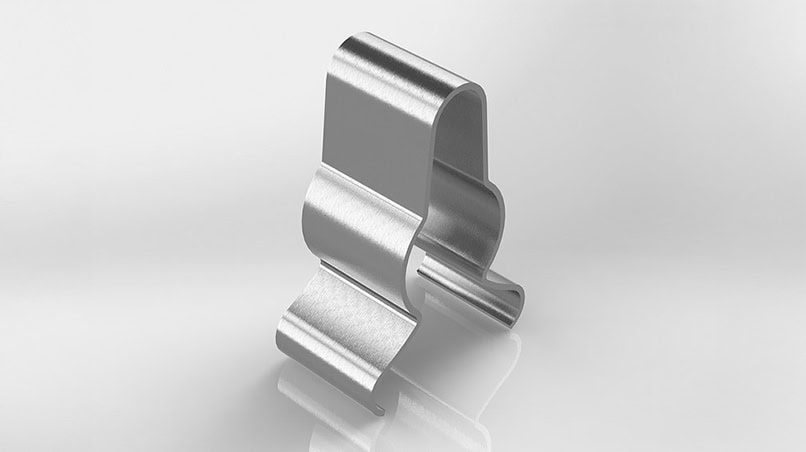

Example application: Special retaining spring for test tube holder

A special holder was needed in a medical laboratory to securely and efficiently hold test tubes in place. The challenge was to develop a spring that automatically picks up the test tube when it is inserted and then holds it straight and firmly. This holder also had to be extremely resilient, as it was used in a device that is continuously filled and emptied.

Schaaf Federn developed a customised retaining spring to meet these requirements. The spring was designed to quickly pick up the test tube and hold it in a precisely aligned position. To ensure durability and reliability, the spring was subjected to extensive testing over 100,000 cycles - and withstood this stress without any loss of function.

Materials and technologies for medical technology applications

High-quality materials for technical springs Schaaf only processes high-quality materials that have proven themselves in medical devices. These include, among others:

- Spring steel and stainless steel such as 1.4310 or 1.4401 for corrosion-resistant applications

- Steel and non-ferrous metals for specific requirements in terms of electrical conductivity, weight or spring characteristics

Customised production Schaaf manufactures:

- Flat springs in straight, moulded or disc-shaped design

- Special solutions for customised devices or clamping mechanisms

The following specifications can be realised:

- Material widths: 1.00 mm - 270 mm

- Material thicknesses: 0.10 mm - 3.00 mm

- Quantities: from one-off production and small series to large series

Flexible production technologies Schaaf uses the following technologies to manufacture precise spring components:

- Laser cutting

- Punching and embossing

- Bending, grinding and assembly

Surface treatment and finishing Schaaf offers the following processes, among others, to ensure that springs function optimally and are durable in the appliance environment:

- Trowalising for smoothing

- Phosphating, burnishing or galvanising for surface protection

- Painting if an optical or functional coating is required

Your advantages with Schaaf springs

As an experienced development partner in medical technology, Schaaf:

- Customised special designs for small batches, series and prototypes

- High flexibility in material selection and geometry

- Support with design, CAD and feasibility analyses

On request: Express service with Production and delivery within 24 hours for time-critical projects

Are you developing a medical device?

We are happy to support you in developing the right technical spring - precisely tailored to your requirements.