It is not only a question of cost-effectiveness, but also of sustainability, if high strength of moulded springs and therefore a long service life in continuous operation is expected. A good knowledge of materials is therefore required in order to be able to offer efficient solutions that guarantee maximum functionality in continuous use. Material strength is a key criterion for sustainable solutions for moulded springs.

What are strength parameters?

The different material - Carbon steel, stainless spring steel or non-ferrous metals - each has a specific strengthwhich is decisive for the use of the moulded spring. The strength says something about the degree of mechanical resistance that is necessary, for example, to achieve a deformation or separation.

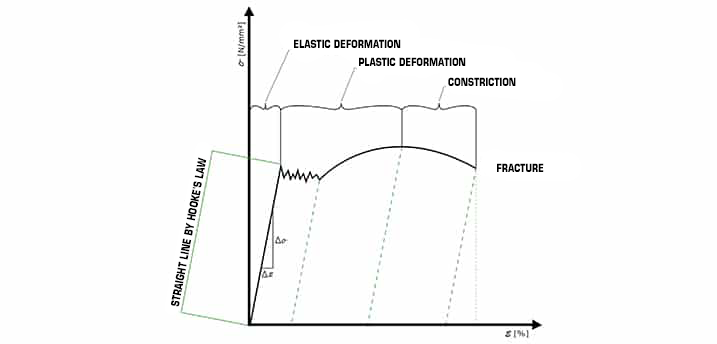

Determination of the strength parameters

- Linear-elastic range

In the linear-elastic range, the elongation is proportional to the stress. - Non-linear elastic range

In the non-linear-elastic range, the deformation is still reversible, but no longer proportional to the stress. - Elastic-plastic area

Finally, there is the elastic-plastic range, in which the deformation is partially plastic and therefore irreversible. If the elasticity limit is exceeded, permanent deformations form in the component.

Influences on the strength of moulded spring materials

- Load strength

- Loading speed

- Type and condition of a material

- Processing temperature

The materials used for moulded springs are influenced by the above factors. As a rule, it is the first two criteria mentioned above that are decisive in the Production of moulded springs the largest Influence on the strength of the moulded spring have. Stress is therefore the key factor in differentiating between the different types of strength.

Load types for moulded springs

A distinction is made between static and dynamic loading.

Static load

In terms of time, the load on the static strength is static.

Dynamic load

The acting force and/or its direction of action change over time.

With the dynamic load, which is also called fatigue strengtha change is given. Here, strength is defined as the deformation and failure behaviour of a dynamically loaded material over a certain number of cycles. This fatigue strength is determined by means of the Wöhler test. This test, also known as the fatigue test, is an important instrument for calculating and verifying fatigue strength and endurance strength.

Differentiation according to the type of load is based on three criteria.

- Tensile strength

The tensile strength describes the highest mechanical stress in the material during a tensile test. - Flexural strength

The bending strength stands for the resistance of a material when bent. - Compressive strength

And finally, the compressive strength describes the resistance of the material under compressive load.

Expertise as a fixed factor

The complexity of Shaped springswhich ultimately lead to a sustainably functional product in continuous use, shows the need for special expertise with the broadest possible practical experience.

These are values that naturally lead to "durable" solutions at Schaaf. Our expertise and experience support your success with products that master even the most specialised requirements with flying colours. Place your trust in a constant on the market: Schaaf!