Contents

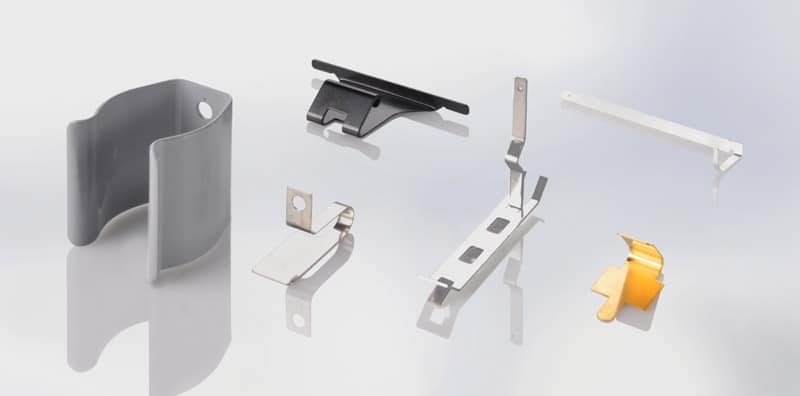

Surface treatments give technical springs special properties. The possibilities of these processes range from optical refinement and special rust protection to higher resilience, electrical conductivity or robustness against heat. In the second part of our overview, we present other processes that help to design technical springs even more individually.

One of the most common processes in the surface treatment of steel springs is phosphating. It is also known under the terms Parkerizing, Bonding or Atramentizing. The different names have one thing in common: It is a treatment technique that is particularly valued for two effects: Favorable sliding properties and temporary protection against corrosion.

Conversion layer is formed on the metallic surface by chemical reactions using a phosphate solution. This consists of firmly adhering metal phosphates and offers the best basic conditions for other applications, for example optimum adhesion promotion for paintwork or those where electrical insulation or the reduction of friction and wear is important. Inexpensive and efficient, it is a widely used method to achieve temporary protection against corrosion.

If the surface of a steel spring is passivated, it has a highly resistant oxide layer and can regenerate itself, thus offering excellent protection against corrosion. Passivation creates a protective layer, the passive layer, either naturally through moisture and oxygen or through passivation chemicals. The resulting layer can slow down corrosion to a very considerable extent. In order to use the process, metallically clean surfaces are required. If passivated naturally, it takes a few days. The use of passivation chemicals reduces the treatment to a few minutes.

Chrome plating is one of the best-known processes in optical surface treatment. In a multi-layer structure, chrome-plated surfaces offer good protection against corrosion and low static friction. Their advantage is that they can be mechanically reworked, have high temperature resistance and do not tarnish. In addition, there is resistance to oxidizing media, abrasion resistance and, last but not least, the decorative aspect.

There are many possibilities for surface treatment of technical springs. The specific application ultimately decides which treatment is functional and efficient. Well-founded advice clarifies this question and – at Schaaf – leads to an individual product that also has the desired lasting effect in terms of surface performance.

Bitte geben Sie hier ihre Suchanfrage ein: