Technical systems are becoming ever more precise, which means that high-tech devices in which precision mechanical devices are integrated are also becoming ever smaller.

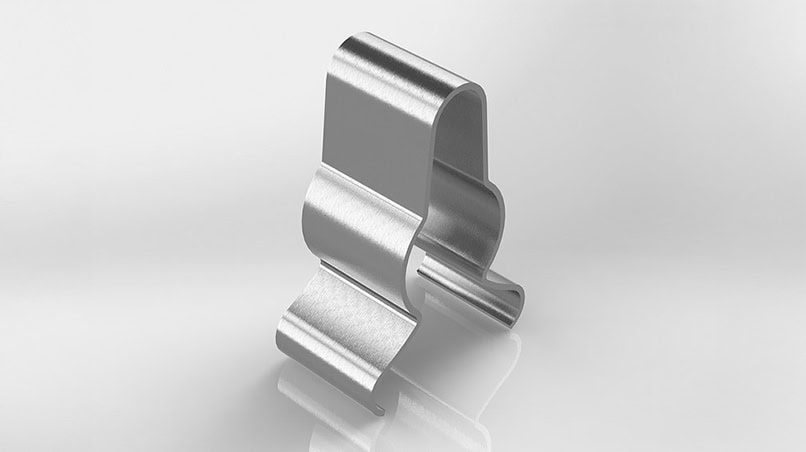

Including: suspension elements with holding, clamping and fixing functions.

When precision matters

Highly complex challenges are solved in the manufacture of precision mechanical products. Accuracy is particularly important here.

History of precision mechanics, timekeeping and the invention of the spring drive

Let's take a brief excursion into history: Everyone is probably familiar with the example of the old watchmaking trade. The earliest written reference to a watchmaker dates back to the 14th century. The watchmaker quickly established himself as a professional group and by the 16th century, watchmakers were already organised in their own guilds. With newer materials, finer tools and the invention of the spring drive, watches could be made smaller and smaller. You could say that watchmakers were the pioneers of precision mechanics.

Due to the increasing demand for "timepieces", numerous manufactories and watch factories developed over the centuries. Originally, every watchmaker produced the finished watch themselves, but over the course of the 18th century, more and more specialisations emerged for the production of certain watch parts. For example, there were wheel and gear makers, chain and Spring makerdial and hand maker.

From the watch spring to the spring for precision mechanics

The spring makers specialised in watch springs such as barrel springs, mainsprings and balance springs. These were made by hand for the precision mechanics in the watches. The development of watch springs made of steel and the development of tools for watch production were accompanied by a reduction in the size of the movement.

In addition to the manufacture of watch springs, production facilities for springs also developed in the 19th and 20th centuries. Springs for precision engineeringthe electrical engineering and toy industries.

The fine art of manufacturing precision mechanical components

The smallest parts and components are produced on precision machines such as milling, turning, drilling and grinding machines. accurate to the micrometre machined. It is a major challenge to manufacture such small components in accordance with all quality requirements! For high-tech industries such as medical technology, electronics, aerospace, measurement and control technology or research and development, these are everyday challenges.

Precision engineering devices and appliances are subject to the highest standards of reliability and quality. Spring technology, among other things, provides a safe and precise interface between the device and its mechanics. It is used to lock and move parts or to close and open switching contacts. Depending on the type and spring type Springs various functions.

Small precision springs customised

For measurement and control technology or for valve technology - areas of use, applications and spring types can therefore be very different - whether as Bent wire partsas Retaining clips or as Flat springs. Standard springs are often not sufficient for complex applications. Customer requirements and requests require customised springs with specific features. Space and cost optimisation are essential and in areas of application such as medical technology, it is clear that Maximum functional reliability and manufacturing quality of the end products must be ensured.

Highly developed manufacturing processes with optical, electronic and acoustic monitoring are therefore used in the production of precision springs, which are used in precision mechanics.

Springs for precision engineering - a customised spring design is usually the best solution

Practical expertise in relation to Spring calculationspring design, spring type, material as well as manufacturing methods and surface treatments are required for demanding applications. If you are looking for a spring for your precision engineering project individual spring solution Mario Schaaf GmbH & CO. KG in the complex field of Spring technology with concentrated expertise available.