In order to manufacture technical springs, which can be found in almost all technical applications, with sustainable functionality, very precise calculations are required. And spring calculation is not without its challenges. A great deal of mathematical and physical understanding is required, from the spring characteristic curve to the spring constant and the spring work. The more customised and purpose-specific the design and geometry of the technical spring, the greater the effort required to calculate the load-bearing segments of the product. Remember: Without brains there is no optimisation and high Quality in technical springs.

Spring calculation means: Calculating the tension work

The mechanical work, which is referred to as tension work, consists of the potential energy that a technical spring generates and stores after being extended or compressed. It is the effect of an external force, i.e. the work that is stored as spring energy when a spring is deformed and released again when the spring is released.

The simple formula does not apply to the spring calculation

We know the formula "work = force x distance" from our physics lessons. As a technical spring is usually pulled in one direction, one could assume that the above-mentioned tension work is also calculated using this basic formula. This is not the case because one element of the equation is not constant: the spring constant. Although the name suggests the opposite, this variable is relative. The spring constant is calculated from the force required to expand the spring, and Hooke's law is applied here. It states that the force required to stretch a spring increases in proportion to the stretched distance. This means that the force to be calculated here is not constant.

Important for the spring calculation: The spring characteristic curve

The calculation of the spring characteristic curve is concerned with the relationship between spring force and spring travel. It clarifies the question of how the technical spring behaves during operation. The design and geometry of the spring determine whether it is a linear, progressive, degressive or combined spring characteristic. It becomes important in connection with the spring constant (see above), which is also referred to as spring hardness or spring stiffness.

The spring characteristic curve represents the course of a spring constant. This physically clarifies how the force to be applied relates to the load on the spring. If the force increases evenly, the spring constant is linear. It is progressive if the force increases disproportionately, and degressive if it decreases disproportionately.

Spring calculation is much more

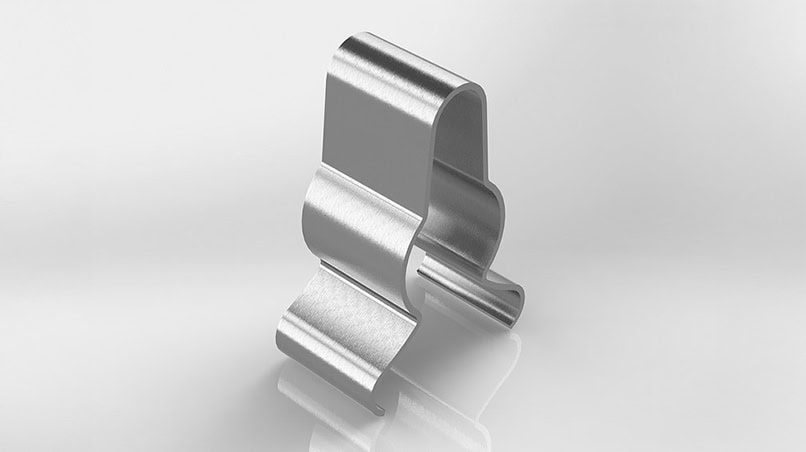

Among the many good ideas that have proven themselves as problem solvers in the form of brackets, some stand out due to their outstanding economic advantages. In its "smart" implementation, a "spring-loaded bracket" not only saves on the bolted installation of the actual bracket, but also on the element to be held. The corresponding components are simply "clipped" together, eliminating not only the cost but also the hassle of usually complicated assembly using screws.

The "contradiction" of a leaf spring or why customisation is often the better choice

Of course, an article of this brevity can only outline a fraction of the mathematical and physical calculations required to produce each individual customised spring. If only the Deformation work mentioned above, there is a lot more to consider. The acceleration work and the lifting work must be considered just as thoroughly, depending on the circumstances. The calculations always have a fundamental effect on the overall production process. They influence the choice of material and machinery, as well as the hardening and/or surface finishing processes. Count on Schaaf when it comes to optimally designed and manufactured customised technical springs!