What does quality actually mean for technical springs?

Sometimes quantity is enough to prove quality. For example, the number 100,000: this is exactly how many strokes and insertions a "pilot" spring had to perform for one of our customers in the medical technology sector without any plastic changes in order to fulfil its requirements. In the field of customised technical springs, it is not uncommon for customer specifications to include special quality assurance measures. But regardless of this, there is a code for us as a manufacturer that defines what Schaaf quality means.

Spring quality starts with purchasing

The keyword for consistent quality assurance is holistic. And this applies equally to processes before and after the actual production. Before the Manufacturing process for moulded springs and technical springs is the purchase of raw materials. Stainless steel of a certain quality is the focus of our selection for the manufacturing processes. In view of the specialities that Schaaf offers, it goes without saying that a meticulous incoming goods inspection is carried out to ensure that no faulty goods are received.

Specifications require permanent spring quality assurance

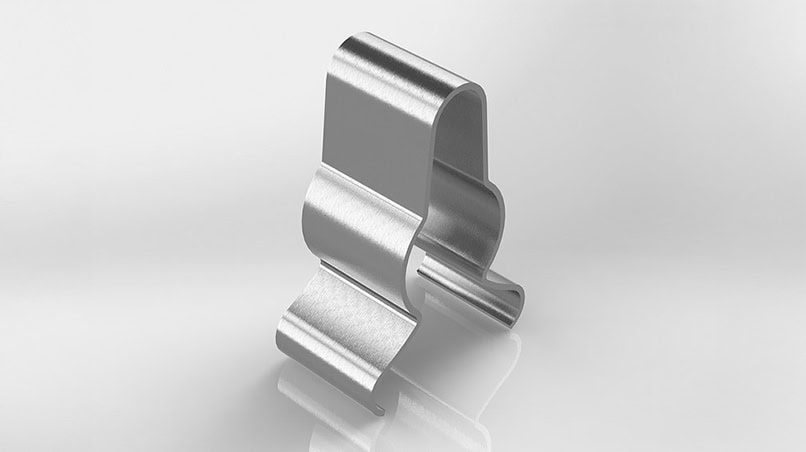

If at Spring steel clamps If a special form and function is required, i.e. if a spring is not standardised, the quality must also be tested beyond the standard. During ongoing production, we repeatedly take products "off the table" according to precisely defined test plans in order to put them through their paces, i.e. to ensure strict compliance with the specifications tailored to them. This is done in our own premises and by specially qualified employees in order to obtain as neutral a judgement as possible. They use state-of-the-art mechanical, optical and electronic testing technology.

Simulants desired for spring quality

Computerised load simulations are one of the services that Schaaf can carry out comprehensively and conclusively on request. More performance can mean fewer potential weak points. And sometimes a real "simulation", as in the case of pipette springs for medical technology described above, replaces any computer.

The advantages of the Quality assurance for springs are obvious: risk minimisation, fast and efficient production and therefore a reduction in costs in the production process.

The "contradiction" of a leaf spring or why customisation is often the better choice

The quality level of products always reflects the "quality" of employees. Those who are driven by the desire to improve will always want to expand their knowledge. Training and further education are therefore a decisive quality factor. As is a good, productive working atmosphere. Motivated employees are a guarantee for better performance. The quality of our products is therefore a reflection of the quality of our employees.

We love challenges and variety. As a family business based in Möglingen, we focus on personal contact and individual support.