Robotics is playing an increasingly important role in industrial production. The number of industrial robots is growing steadily and the areas of application are no longer limited to the automotive industry, but are increasingly extending to other sectors as well. But what do technical springs have to do with robotic systems?

Universally applicable movement machines

The number of robots in industry is growing rapidly. Robots are installed in companies and factories all over the world, performing measuring, manufacturing and handling tasks and are a routine part of the production process in many industrial applications. Over the past five years, the average robot density worldwide has almost doubled. "Robot density is an important indicator for understanding the differences in the degree of automation in different economies," explained Milton Guerry, President of the International Federation of Robotics (IFR).

Examples of fields of application for industrial robots:

- Vehicle construction

- Mechanical engineering

- Warehouse logistics

- Medicine and chemistry

- EDP and electronics

- Precision mechanics

- Food and luxury foods

- Rubber and plastic goods

- Casting industry

Examples of activities performed by industrial robots:

- Measuring, testing, checking, etc.

- Fastening, mounting, dismounting

- Gripping, inserting and loading

- Soldering, inert gas welding, spot welding, laser welding

- Laser cutting, plasma cutting, water jet cutting

- Mechanical processing of workpieces

- Surface treatments

- Loading and unloading

Springs in robotics

In order to utilise robots profitably in production, movement functionalities are required that cannot do without technical springs. On the contrary, one could even claim that Springs at the heart of the robot systems because they are elementary and are often at the centre of a construction, where they ensure the smooth functioning of the machine. Springs connect, interlock, lock, pull or press on. They hold firmly, bend or move and can provide relief through intelligently utilised damping properties.

Technical springs for the future of industry

Fixing, controlling and braking or repeatedly connecting and disconnecting moving parts enables robotic systems to carry out controlled and rigid, yet extremely complex movement processes.

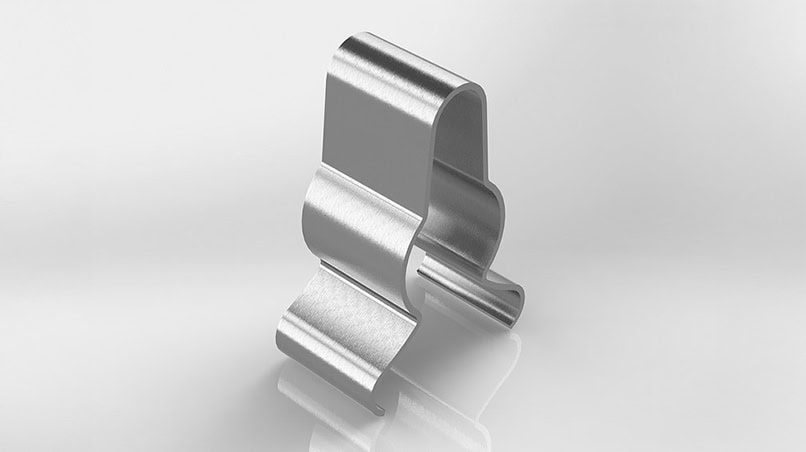

In order to be able to technically realise dynamic movements similar to human joints, muscles and tendons Spring clips with a certain clamping force. Particularly "ingenious" holders make an indispensable and efficient contribution when it comes to reproducing human body movements such as targeted holding and fixing.

However, limited space and complicated shapes often make it impossible to realise a simple Spring calculation and interpretation. In this respect State-of-the-art technical expertise This means that the right manufacturing process can be used for each spring.

State-of-the-art production and finishing

Expertise in all areas of the entire production process determines the efficiency and sustainability of a single tensile, compression or Clamping spring have an effect.

You can count on Schaaf when it comes to optimally designed and manufactured customised technical springs. Our dedicated team, state-of-the-art production techniques and the breadth of our capabilities are the guarantee for excellent Shaped springs and Bent wire parts.

Mario Schaaf GmbH & CO. KG is at your disposal with all its experience - even and especially when it has to be very special.