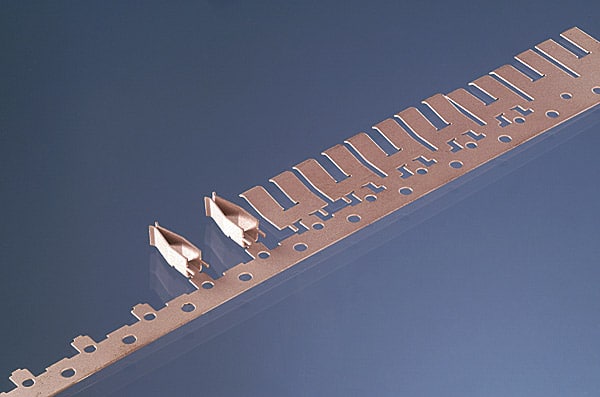

EMC contact springs are spring elements to avoid electromagnetic interference. Designed for a specific functionality, they enable the smooth operation of machines and systems by preventing electromagnetic or electrostatic interference.

Customer-specific solutions that go beyond the standard are also required in the manufacture of EMC contact springs, and Schaaf is a top address for the implementation of these.

Contents

EMC: Electromagnetic Compatibility

The term EMC stands for electromagnetic compatibility and plays a role in machines and systems in which electrical drives operate. The aim of EMC measures is that various electronic devices can be operated in the immediate vicinity without causing disruptive interference.

EMC is the ability of a technical device not to disturb other devices through electrical or electromagnetic effects.

EMC contact springs avoid electromagnetic fields and absorb mechanical vibrations. The spring elements are designed to prevent errors such as interactions and feedback inside and outside the device by effectively diverting interference currents.

EMC spring contacts ensure that interference fields cannot cause any damage!

A large number of machines and production systems are powered electrically these days. Depending on the application, such a drive can be continuously controlled, which is done using frequency converter technology.

In addition to numerous advantages, frequency converter technology also has the disadvantage of emitting strong electromagnetic interference fields via the motor connection cable. Without EMC shielding, it could happen that sensor lines interpret this as a signal and switch on the wrong functions. High overvoltages are also possible in the line. In such cases, EMC springs ensure that interference fields cannot cause any damage.

Because of the particularly good material properties, EMC springs are mainly made of galvanized spring steel or copper alloys such as copper beryllium. In addition to the areas of application mentioned above, in electrically driven machinery, there are the following branches of industry in particular in which EMC contact springs are used at static and dynamic locations.

Application branches for EMC contact springs:

How is the quality of EMC contact springs checked?

A consistent quality concept is important for contact springs for EMC applications. The quality of the springs is measured from the product development through the production-accompanying tests up to the final test.

EMC tests

For the optimal functioning of EMC contact springs, there are EMC tests in which the immunity to external interference is examined. In addition to EMC measurements as part of this test, measurements of the shielding effectiveness are also carried out. In both cases, a fundamental distinction is made between line-bound interference and interference that is triggered by electrical and magnetic fields or radio waves.

EMC regulations

Different EMC regulations depending on the area of application: EMC tests are based on different requirements for electrical or electronic systems. So it makes sense that the reliability of aircraft is more demanding than that of consumer electronics.

Accordingly, the specific test and measurement methods in information technology, industrial, automotive, aerospace, military and medical technology are different.

Experience and know-how are decisive criteria for those who do not want to make any compromises when it comes to electromagnetic compatibility and contact springs for EMC applications.

Schaaf is a partner that numerous companies trust when high-precision contact springs of special quality are required. As specialists for tricky tasks as well as for standard solutions, the Schaaf experts look forward to finding the best possible solution to your problem.

Bitte geben Sie hier ihre Suchanfrage ein: